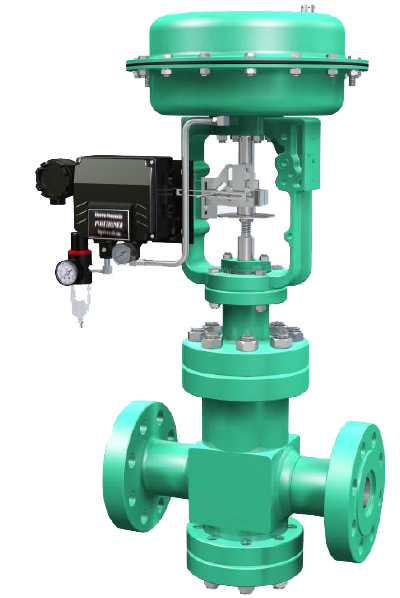

EHD – Multistage Minimum Flow Control Valve

EHD multistage cage control valve used a multilevel cage symmetric sleeve control valve.

It complete control medium velocity within the valve, and greatly reduced noise made by high-pressure gas or steam within the valve, stabile multistage pressure reducing effective prevent liquid cavitation, so it’s the stable control valve used in high-pressure medium performance, customers can also select multi-spring diaphragm mechanism or pneumatic actuators

Body Type

Nominal Diameter

Nominal Pressure

Connection

Flange Distance

Bonnet Type

Packing

Sealing Gasket

Actuator

Valve Disc type

Flow Characteristics

Direct casting ball-type valve

DN20, 25, 32, 40, 50, 65, 80, 100, 200

PN 1.6, 2.5, 4.0, 6.4, 10.0, 16、25Mpa CLASS 150, 300, 600, 900、1500Lb

Flange: FF, RF, RTJ, welding: SW, BW

according to IEC534

Standard type, lengthened (heat dissipation, low temp, bellows sealing).

V type PTFE, flexible graphite

Metal with graphite gaskets

Pneumatic, multi-spring actuator. Electric: 3810L series, PSL series.

multistage cage sleeve type.

standard material composition and applicable temperature, pressure range, please refer to appendix.

Material and internal structure

- The above is standard configuration structure, the valve seat is metal to metal, and we can still provide strengthen trim with stellate alloy coating. For specific applicable temperature, we have more reasonable bolts, nuts for choose.

- PTFE v-shaped ring stem packing is the standard configuration and can also choose flexible graphite.

- Standard body material is carbon steel and stainless steel, and we can still provide various high corrosive-resistance alloy materials.